A Corporate Guide to Vending Machine Moving & Relocation

- vendmooreenterpris

- Aug 16, 2025

- 12 min read

Relocating a vending machine is a precise logistical operation, not a simple task of heavy lifting. For facility managers and operations directors, a seamless vending machine move is critical to preventing asset damage, avoiding costly downtime, and ensuring employee amenities remain uninterrupted. A successful relocation hinges on meticulous pre-move preparation. Overlooking these critical steps often leads to internal damage to sensitive payment systems or refrigeration units, resulting in unexpected repair costs and service disruptions.

This guide outlines the professional protocol for safe and efficient vending machine moving, tailored for corporate environments.

The Pre-Move Vending Machine Checklist for Facility Managers

This foundational stage is designed to protect both the machine's complex internal components and its external casing. Adhering to this professional checklist minimizes the risk of operational failures and ensures the asset is protected throughout the relocation process, saving your organization from future repair expenses and downtime.

Empty All Products and Cash

First, the machine must be completely emptied to reduce its gross weight. All products—beverages, snacks, and fresh food—must be removed. An unsecured item can dislodge during transit, potentially damaging internal mechanisms, delivery systems, or the glass front.

Equally important is the removal of all currency from the coin mechanism and bill validator. This secures company revenue and, critically, reduces stress on sensitive electronic components that can be damaged by the weight and vibration of shifting coins during the move.

Disconnect Power and Secure the Cord

Adherence to safety protocols is non-negotiable. The machine must be fully powered down and disconnected from its electrical source before any physical movement occurs. Attempting to relocate a live, powered machine presents a significant electrical hazard.

Once unplugged, the power cord must be coiled securely and fastened to the back of the unit with industrial tape or a zip tie. A loose cord is a primary cause of workplace accidents during a move, creating a tripping hazard and risking damage to the cord, plug, or outlet if snagged.

Professional Note: A dangling power cord is one of the most common—and entirely avoidable—causes of accidents during a vending machine relocation. Securing it properly is a key step in any professional safety protocol.

Perform a Thorough Cleaning

Pre-move cleaning is a preventative maintenance measure. Over time, dust, crumbs, and beverage residue accumulate inside the unit. The vibrations from a move can dislodge this debris, forcing it into critical components like cooling fans, control boards, or payment system sensors, leading to post-move malfunctions. A thorough vacuum and wipe-down can prevent these future service calls.

Should you encounter operational issues beyond simple cleaning, it's vital to engage professional technicians. Learn more with our corporate guide to reliable vending machine repairs.

Maintaining equipment integrity is crucial in a competitive market. The global vending machine market reached USD 23.16 billion in 2024 and continues to expand as businesses demand reliable, convenient service. Keeping your assets in prime condition is essential for operational excellence.

Pre-Move Preparation At a Glance

This checklist provides a clear overview for tracking essential preparation tasks, ensuring no critical step is missed before the relocation begins.

Task | Purpose | Status |

|---|---|---|

Empty All Products | Reduce weight and prevent internal damage from loose items. | ☐ Complete |

Remove All Cash/Coins | Secure revenue and prevent damage to electronic components. | ☐ Complete |

Unplug Machine | Ensure electrical safety before any physical handling. | ☐ Complete |

Secure Power Cord | Prevent tripping hazards and damage to the cord or plug. | ☐ Complete |

Clean Interior/Exterior | Prevent debris from causing malfunctions post-move. | ☐ Complete |

Once each item on this checklist is complete, the vending machine is properly prepared for a safe and successful relocation.

Gathering Your Essential Moving Equipment

Attempting to move a vending machine without specialized equipment is a significant liability, risking damage to the asset, your facility, and personnel. Standard warehouse tools are insufficient for this task. The use of professional-grade equipment is not a luxury; it is a fundamental requirement for protecting your investment and ensuring a safe operation.

The cornerstone of any vending machine move is a heavy-duty appliance dolly. A standard hand truck lacks the structural integrity and capacity required. Appliance dollies are engineered to manage the substantial weight (often 600-800 lbs) and dimensions of commercial vending machines. Key features must include a high weight capacity, large-diameter wheels for smooth transit, and robust strapping mechanisms to secure the machine. An unsecured machine is the single greatest risk during a move; a high-quality dolly is the primary tool for mitigating it.

Protecting the Machine's Finish and Glass

Once the proper dolly is secured, the next priority is protecting the machine's exterior surfaces. Dents, scratches, and cracked glass are common results of improper handling but are entirely preventable with correct preparation.

Essential protective materials include:

Thick Moving Blankets: These are non-negotiable for cushioning the unit. They absorb impacts and prevent scratches to the metal frame and painted surfaces during transit.

Industrial-Grade Shrink Wrap: After blanketing, the entire machine should be wrapped in multiple layers of shrink wrap. This secures the blankets, prevents them from shifting, and adds a durable outer layer of protection.

Cardboard Corner Protectors: These should be applied to the machine's corners before wrapping. They distribute the immense pressure from the dolly's securing straps, which can otherwise dent the frame.

The Right Vehicle and Tools for the Job

Even with a fully prepared machine on a dolly, the logistics are incomplete without the right vehicle and tools. A standard pickup truck is inadequate and unsafe for this type of transport.

A box truck equipped with a functional hydraulic liftgate is mandatory. The liftgate provides the necessary power to safely raise the machine from ground level to the truck bed. Attempting to manually push a machine up a ramp is exceptionally dangerous and risks catastrophic failure. A liftgate ensures a controlled, safe loading process.

A common oversight is failing to address the leveling feet. These components can be easily bent or broken during a move. A basic toolkit with the correct wrench is all that is needed to remove them prior to relocation.

A comprehensive understanding of the machine's components is advantageous. For deeper insight, our guide to vending machine mechanics for modern businesses explains how these complex systems operate. Ensuring you have the right equipment on hand guarantees that every part of your vending machine arrives at its new location in perfect operational condition.

How to Properly Pack and Secure Your Machine

Professionally packing a vending machine is a systematic process that goes far beyond simple covering. Improper packing is a leading cause of cosmetic damage and internal component failure during transit. A machine in transit is subjected to constant vibration and potential impacts; meticulous packing ensures it arrives ready to serve your employees, not generate a repair invoice.

Your primary protective layer is a set of high-quality, heavy-duty moving blankets. Cover every external surface to create a thick, cushioned barrier. This is the most effective way to protect large glass fronts and painted finishes from abrasions and impact.

With the blankets in place, use industrial-grade shrink wrap to secure the entire package. Begin at the base and work upward, overlapping each layer by approximately 50%. This process serves two functions: it holds the protective blankets firmly in position and unitizes the machine into a solid, stable block for safer handling.

Securing Internal and External Parts

Protecting the exterior is only part of the equation. Unsecured internal components can cause significant damage from rattling during the move. Forgetting to secure these parts is a common mistake that can result in broken delivery trays, dislodged spirals, or damaged wiring.

Before wrapping, open the machine to inspect and secure internal elements.

Delivery Bin: Use zip ties or heavy-duty tape to immobilize the delivery bin or chute, preventing it from swinging and sustaining damage.

Shelves and Spirals: Ensure that all product spirals and trays in glass-front machines are secure and cannot shift or fall out of their tracks during transit.

These preparatory steps are essential for preventing unnecessary post-move repairs.

Insider Tip: Utilize cardboard corner protectors. Place these on all four corners of the machine before applying shrink wrap. The tension from dolly straps is concentrated on these corners; these protectors prevent dents and structural damage to the frame.

Final Touches for a Secure Move

Once the machine is fully wrapped with internal components secured, you have created a stable, protected unit that is significantly safer to transport. This level of preparation is the standard for professional movers and is the key to a successful, damage-free relocation.

The physical protection of the machine is as vital as understanding its internal technology. Modern vending machines are sophisticated assets. For a deeper look into their advanced capabilities, explore our corporate guide to modern vending machine technology.

Making the Move Safely and Smartly

With the machine prepped and equipment ready, the physical relocation begins. This phase requires technique and clear communication, not brute force. A calm, methodical approach is the best defense against property damage, asset loss, and workplace injury.

First, position the appliance dolly correctly. Slide the dolly's base plate completely underneath the machine, ensuring it is perfectly centered. Identifying the machine's center of gravity is the most critical aspect of this step. An off-center placement will cause the heavy unit to become unstable and difficult to control.

Once centered, secure the machine to the dolly. Use the provided straps and tighten them with the ratchet mechanism until there is absolutely zero movement. Any slack allows the machine to shift its weight unexpectedly, creating a serious tip-over hazard.

Getting Through Tight Spots and Onto the Truck

Moving an 800-pound, top-heavy machine requires a coordinated team. The operator steering the dolly from behind directs the move, while a spotter positioned in front acts as their guide, clearing the path and navigating obstacles.

Navigating doorways and corners demands precision and patience.

Doorways: Approach doorways head-on whenever possible. If an angled approach is necessary, proceed slowly and deliberately, ensuring all corners of the machine clear the frame.

Corners: Execute wide turns. The spotter must monitor both the leading and trailing corners to prevent collisions with walls and fixtures.

Communication: Use clear, simple commands. "Stop," "left," and "watch the corner" are effective and prevent confusion, ensuring team safety.

These precautions are especially vital in corporate or managed facilities where property damage can harm business relationships. For more on maintaining commercial spaces, review these facility management best practices for 2025.

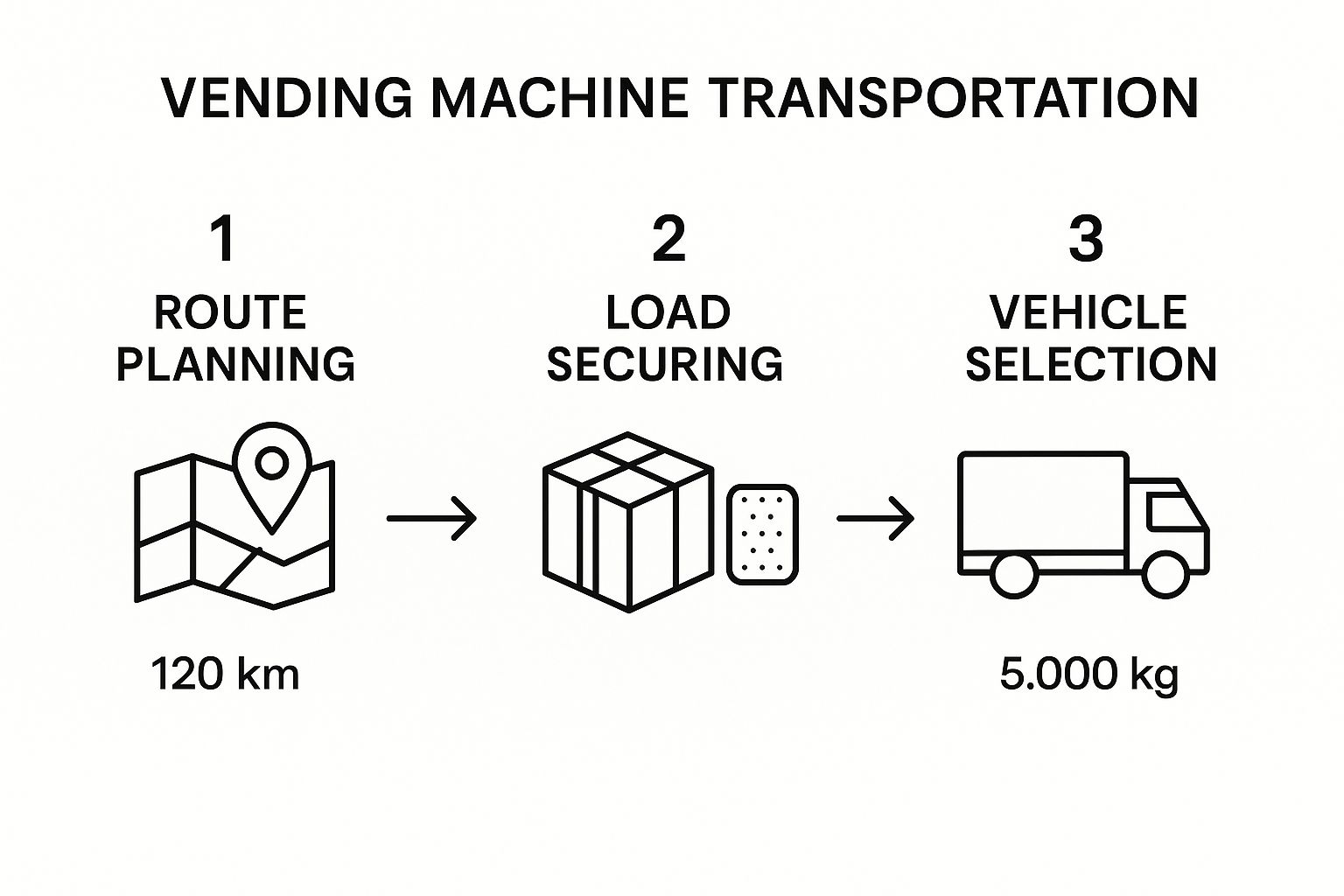

The entire process, from planning to execution, follows a professional workflow.

As illustrated, a successful move is founded on strategic route planning, secure loading procedures, and the use of appropriate commercial vehicles.

The Right Way to Load a Vending Machine

Upon reaching the moving truck, the hydraulic liftgate is essential. Attempting to maneuver a vending machine up a ramp is unacceptably dangerous and violates professional safety standards.

Carefully roll the dolly onto the center of the liftgate platform. One team member should operate the liftgate controls while another maintains a firm grip on the dolly to ensure stability as it ascends.

The cardinal rule of professional moving is: never rush. Slow, controlled movements are always safer and more effective than attempting to force the machine into position.

This careful methodology is standard in the vending industry. North America dominates the global market with a 45% share, and the U.S. market alone was valued at USD 6.79 billion in 2024, reflecting a high professional standard. Once inside the truck, position the machine against the front wall and use additional ratchet straps to secure it, preventing any movement during transit.

Final Installation and System Checks

The relocation is complete, but the process is not finished. Rushing the final installation steps is a common error that leads to malfunctions and immediate service calls. A systematic recommissioning process is required to ensure a successful deployment.

First, do not plug the machine into a power source immediately. The unit must rest, unplugged, for a minimum of 2-4 hours. During transit, the refrigerant and oils within the cooling system are agitated. Powering the unit on prematurely can cause irreparable damage to the compressor—a costly and avoidable repair.

Getting the Machine Perfectly Level

While the machine rests, reinstall the leveling feet that were removed prior to the move. Achieving a perfectly level placement is critical for proper mechanical function, not just for aesthetics.

An unbalanced machine will lead to operational issues, including:

Jammed Products: A slight tilt can cause products to hang up in dispense spirals or drop incorrectly, leading to failed vends and customer frustration.

Poor Door Seals: An uneven frame can prevent the door from sealing correctly, causing the cooling unit to run continuously and leading to premature failure.

Instability: An unstable machine that rocks during use appears unprofessional and can be a source of frustration for users.

Use a carpenter's level on top of the machine and adjust each leveling foot until the unit is perfectly balanced. This simple step significantly impacts the machine's long-term reliability and performance.

Pro Tip: Allowing the machine to rest unplugged for several hours post-move is a mandatory step. This allows the compressor's refrigerant and oils to settle, preventing catastrophic cooling system failure.

Running a Full Systems Check

After the rest period, and once the machine is level, it can be plugged in to begin a full systems diagnostic. This final check confirms that all components are functioning correctly after the move and are ready for employee use.

Begin with the cooling system. After approximately one hour, verify that the internal temperature is cooling effectively. Next, test every product selection. Run a test vend from each slot to ensure all motors and spirals are operational.

Finally, validate all payment systems. Test the coin mechanism, bill validator, and cashless payment reader to confirm they are online and processing transactions correctly. This diligence ensures your vending service is fully restored and ready to generate revenue.

With the vending market's revenue projected to grow from USD 21.6 billion in 2024 to nearly USD 41.4 billion by 2033, operational uptime is more critical than ever. For a detailed analysis of market trends, see these vending industry projections and the full forecast.

Common Questions About Moving a Vending Machine

Even with a detailed plan, facility managers and business owners often have questions regarding the logistics, costs, and safety of moving a vending machine. Addressing these concerns proactively ensures a smooth process without last-minute complications.

A primary consideration is whether to manage the move in-house or hire a professional service. While a DIY approach may appear to reduce initial costs, it introduces significant risks. The potential for damage to an expensive asset, facility infrastructure, or—in the worst case—personnel injury must be weighed carefully. The specialized equipment and expertise of professional movers are almost always a prudent investment.

Another common concern involves navigating logistical challenges like stairs, tight corridors, and elevators. Without proper equipment, such as a stair-climbing dolly, these obstacles can transform a straightforward move into a hazardous and costly undertaking.

Should I Move the Vending Machine Myself or Hire a Pro?

This critical decision comes down to a simple equation: cost versus risk. For a corporate entity, mitigating risk is paramount.

An in-house, or DIY, move requires renting a heavy-duty appliance dolly, a truck with a liftgate, and purchasing all necessary supplies. While this may reduce the direct invoice cost, your organization assumes 100% of the liability. Any damage to the machine, property, or injury to staff falls under your responsibility.

Professional movers arrive with the correct equipment, extensive experience, and, most importantly, comprehensive liability insurance. Their expertise in handling heavy, awkward equipment drastically reduces the risk of an incident and ensures the asset arrives in perfect working condition.

An often-overlooked factor is business disruption. A professional move is significantly more efficient, minimizing the time your vending service is offline. A DIY move that results in damage could lead to days or weeks of lost service while awaiting repairs.

DIY vs. Professional Mover Cost-Benefit Analysis

This table provides a clear comparison to aid in your decision-making process, highlighting the true value of a professional service for a business.

Factor | DIY Move | Professional Service |

|---|---|---|

Upfront Cost | Lower (equipment rental, supplies) | Higher (service fee) |

Equipment | Must source and rent all specialized gear. | All necessary equipment is provided. |

Labor | Requires internal staff resources. | Experienced, trained crew included. |

Risk of Damage | High; organization is fully liable for asset and property. | Low; covered by mover's liability insurance. |

Risk of Injury | High; lack of experience increases potential for accidents. | Very Low; crew is trained in safety protocols. |

Downtime | Potentially longer due to inexperience or damage. | Minimal; move is efficient and streamlined. |

From a risk management perspective, the higher upfront cost of a professional service provides significant long-term value and peace of mind.

How Much Does Vending Machine Moving Cost?

The cost of moving a vending machine is not standardized; it is based on the specific requirements of each job. A professional quote will be influenced by several key factors.

Here’s what a professional service will assess when preparing an estimate:

Distance: Relocating a machine within the same building will cost less than transporting it to another corporate campus across town.

Obstacles: The presence of stairs, tight corners, elevators, or other navigational challenges will impact the labor and time required, affecting the cost.

Machine Size & Weight: Moving a large combination or frozen food vending unit requires more resources than moving a standard snack machine.

Accessibility: Easy access for a box truck at both the pickup and delivery locations will result in a lower cost. Difficult loading docks or long distances from the entrance will increase the price.

The best course of action is to request a custom quote. A reputable service provider will often conduct a site survey to accurately assess the scope of work before providing a firm price.

This tailored approach is the hallmark of a true vending partner. To learn more, read about the importance of customer input in vending machine services. A premier provider listens to your unique business needs and builds their service model accordingly.

Managing a vending machine relocation requires expertise, precision, and a commitment to safety. At Vendmoore, we provide comprehensive vending management solutions for businesses, from seamless installations and relocations to customized product stocking and proactive maintenance. If your Oklahoma-based company needs a reliable vending partner dedicated to exceptional service, we are ready to assist.

Discover our tailored vending solutions for corporate clients at https://www.vendmoore.com.

_edited.png)

Comments