A Guide to Vending Machine Mechanics for Modern Businesses

- vendmooreenterpris

- Aug 15, 2025

- 12 min read

Ever wondered what really happens inside a vending machine when an employee grabs a mid-day snack? It’s not just a big box that dispenses products. Think of it as a miniature, fully automated retail point, complete with a secure payment processor and a precise inventory system, all working in perfect harmony to support your workplace.

This automated process has been refined for over a century, a far cry from the first vending machines that sold postcards in London back in the 1880s. Those early models were purely mechanical, relying on simple weights and levers. Today's technology is a world away, offering reliability and convenience that modern businesses expect. If you're curious, you can learn more about the vending machine market history and its projected growth.

The Journey of a Vending Machine Purchase

Let's break down the seamless transaction process. The entire purchase is a sophisticated, two-act play starring an automated payment system and an internal dispensing mechanism, designed for speed and accuracy.

Act 1: The Automated System Processes the Order

First, the machine must securely handle the payment. When a user inserts a coin, slides in a dollar bill, or taps a credit card, a set of sophisticated sensors and validators activates.

Payment Validation: A bill acceptor uses optical scanners to verify currency and reject counterfeits. The coin mechanism measures the exact size, weight, and metallic properties of each coin. Modern card readers communicate with banking networks to authorize a transaction in seconds.

Selection Recognition: Once payment is approved, pressing a selection button sends an electrical signal to the machine's main control board. The order is now officially placed and ready for fulfillment.

Act 2: From Signal to Product Delivery

Now, the internal mechanics get the message. The control board—the machine's brain—processes the selection and instructs the correct motor to activate. This is where the core vending machine mechanics truly shine.

At its heart, the control board's job is to translate a button press into a physical action. It determines which motor to spin, how much to turn it, and then confirms the task is complete—all within seconds to ensure a smooth user experience.

A small motor whirs to life, turning a metal spiral coil. This coil carefully nudges the chosen item forward until it tips over the edge and tumbles into the collection bin.

This simple, effective system is what makes modern vending so reliable. It's an automated workflow engineered for one purpose: to deliver the right product, every single time, keeping your employees and clients satisfied.

Inside the Machine: A Look at the Core Mechanical Parts

To fully appreciate why a modern vending machine is so dependable, you need to understand the components working inside. It's not just a simple box; it's a finely tuned system where every part has a critical job. Think of it as a compact, automated warehouse, engineered to place the right product in your team's hands, every time.

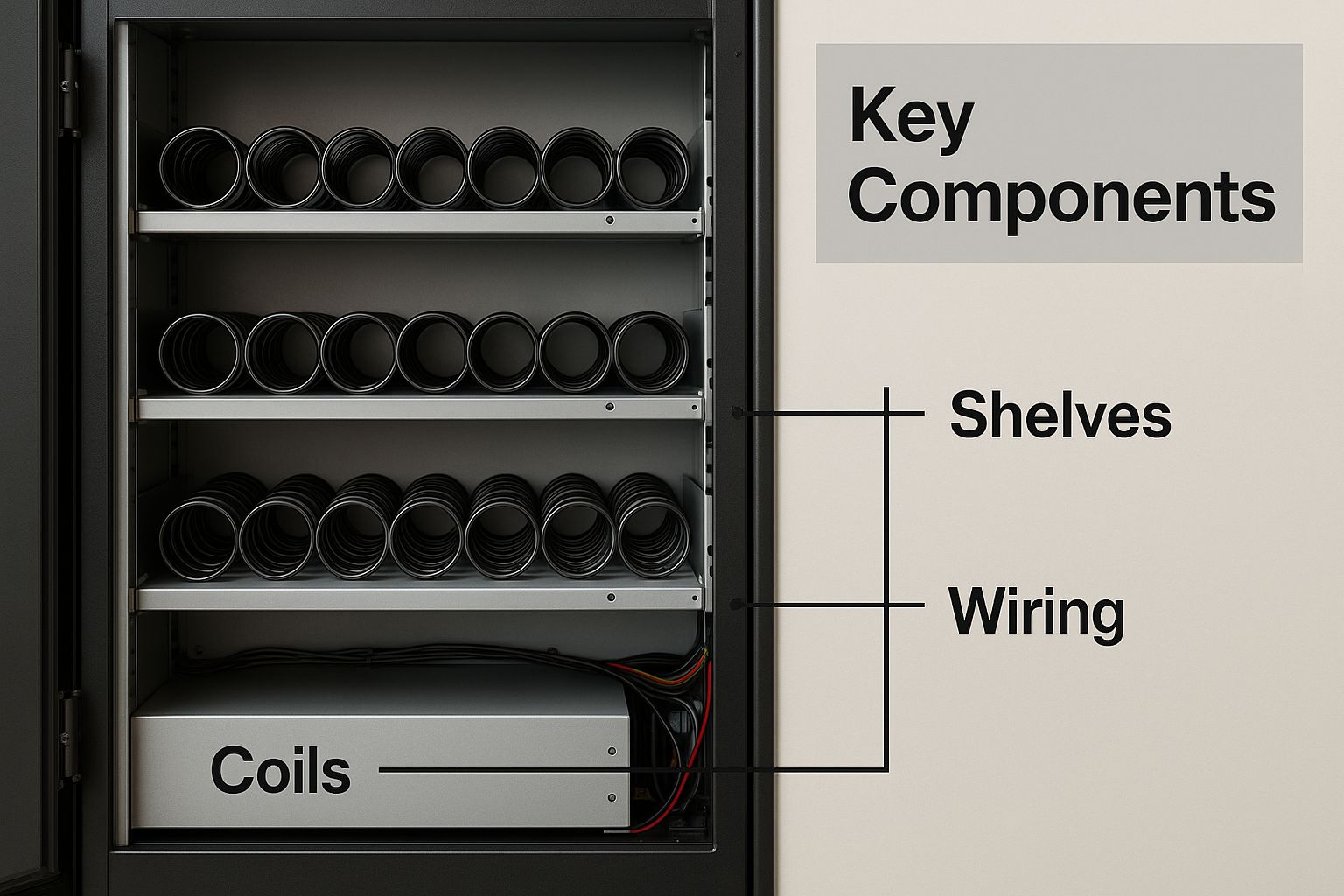

This image provides an excellent cutaway view of how these components integrate and function.

You can see how dispensing shelves, payment systems, and the main controller are all engineered into a compact space to make the entire process seamless and reliable for your facility.

Let's break down the most important parts.

Dispensing Mechanisms: The Workhorses of Vending

The first thing most people think of is the dispensing system—the part that actually moves the product. The classic spiral coil remains the industry standard for sturdy items like chips, candy, and cookies. A small motor provides a precise turn, pushing the snack forward just enough to tip it into the retrieval bin. Simple, effective, and highly reliable.

But what about items that require more careful handling? You can't just drop a glass bottle or a fresh sandwich. That's where more sophisticated systems are essential for a premium vending program.

Conveyor Belts: These are ideal for more delicate items. The belt gently carries the product forward and drops it into a central collection area before moving it down to the user.

Elevator Systems: For the most fragile products, an elevator is the gold standard of care. A small platform travels to the correct shelf, carefully retrieves the item, and lowers it safely to the bin. No drops, no damage.

These advanced mechanisms are what allow modern vending services to offer a diverse product mix, from traditional snacks to healthy salads or cold-brew coffees, catering to all employee preferences.

Payment Systems: The Gatekeepers

Of course, no transaction begins until payment is made. The payment system acts as the machine's secure gatekeeper, built for both accuracy and security. Traditional coin mechanisms and bill validators use a series of sensors to check the weight, size, and even the magnetic signature of currency to spot fakes.

Today, cashless readers are a corporate standard. They connect to banking networks in seconds to authorize credit cards, debit cards, and mobile payments. This ensures every transaction is legitimate, protecting both the user and your vending partner. It's this kind of component reliability that highlights how Vendmoore's attention to detail is revolutionizing vending machine services, because dependable hardware is non-negotiable for a corporate environment.

The Brain and Senses of the Machine

Running the entire operation is the Vending Machine Controller (VMC). This is the machine’s central processing unit. It receives the user's selection from the keypad, waits for authorization from the payment system, and then instructs the correct motor to begin its cycle.

The VMC orchestrates every single step. It’s not just telling a coil to spin; it’s confirming payment, selecting the correct product, and ensuring successful delivery.

To verify a successful vend, the VMC relies on a network of sensors. One of the most critical is the drop sensor, usually an infrared beam near the bottom of the machine. If a product is supposed to drop but fails to break that beam, the VMC recognizes an error—the item is likely stuck.

Instead of failing the transaction, it can attempt to spin the coil again or automatically issue a refund. This intelligent feedback loop is what separates a modern, "smart" machine from older models and guarantees a positive user experience.

Key Vending Machine Components and Their Functions

This table summarizes the key components inside a typical machine and their functions, helping facility managers understand the technology they are bringing on-site.

Component | Primary Function | Best For These Products |

|---|---|---|

Spiral Coil | Rotates to push a product off the shelf. | Chips, candy bars, pastries, and other packaged snacks. |

Conveyor Belt | Gently carries products to a central drop point. | Sandwiches, wraps, and other delicate, wider items. |

Elevator System | Lifts to a shelf and carefully lowers the product. | Glass bottles, salads, fruit cups, and very fragile items. |

Bill/Coin Validator | Scans and verifies cash and coin currency. | All products in machines that accept physical currency. |

Cashless Reader | Processes credit/debit cards and mobile payments. | All products; essential for higher-priced and fresh food items. |

VMC (Controller) | The "brain" that coordinates all functions. | Universal component in all modern automated machines. |

Drop Sensor | Confirms a product has been successfully vended. | Universal component; crucial for guaranteeing a vend. |

Understanding these components makes it clear that a vending machine is far more than a simple box—it’s a sophisticated piece of automated retail technology designed for the modern workplace.

The Tech That Makes Modern Vending Tick

Forget the clunky, coin-only machines of the past. Today's vending solutions are smart, connected retail hubs built for convenience and rock-solid reliability. For business leaders and facility managers, understanding the technology inside these machines is key to selecting a service provider that meets the expectations of a modern workforce. At the heart of it all is connectivity, which transforms isolated boxes into a smart, responsive network.

This connectivity is powered by telemetry, a system that allows operators to monitor their machines remotely. Think of it as a constant health check running in the background. It transmits real-time data on inventory levels, sales trends, and operational status, ensuring a machine is restocked long before it runs empty.

Live Inventory and Smart Analytics

Telemetry completely transforms the traditional vending service model. Gone are the days of operators arriving on a fixed schedule, regardless of need. Now, restocking visits are data-driven. This intelligent approach means the products your team loves are always available, and underperforming items can be replaced based on actual consumption patterns.

For your business, this translates to fewer employee complaints about sold-out items and minimal disruption from service technicians, since every visit is efficient and purposeful.

The real power of modern vending tech is its ability to anticipate needs. By tracking sales and stock levels in real-time, operators maintain optimal inventory, which is a significant win for employee morale and a major relief for facility managers.

Beyond inventory management, these systems generate valuable insights. A quality provider can identify which healthy options are popular in your breakroom or which beverages are in high demand during the afternoon. This data allows them to tailor the product mix perfectly to your workplace culture. You can get a much deeper look at this in our corporate guide to modern vending machine technology.

A Better, Smoother User Experience

The technology hasn't just improved backend operations; it has completely transformed the user interface. Clunky buttons and temperamental coin slots are being replaced by sleek, intuitive interfaces that feel more like using a tablet.

This leap forward is driven by several key upgrades:

Interactive Touchscreens: Large, bright touchscreens allow users to browse products, view nutritional information, and even add multiple items to a cart for a single checkout.

Convenient Cashless Payments: Accepting credit cards, debit cards, and mobile wallets like Apple Pay or Google Pay is now standard. This removes the friction of needing exact change or cash.

Energy-Efficient Systems: Modern machines are designed with LED lighting and high-efficiency cooling, which reduces energy consumption and helps lower your building's operational costs.

Another huge step forward in vending machine mechanics is the move toward touchless technology. The latest models allow users to scan a QR code with their phone to browse and purchase, all without touching the machine's surface. A sophisticated network of sensors and processors handles the rest. As current vending machine statistics on news.market.us show, these innovations are driven by a strong corporate demand for safer, more hygienic workplace amenities. Ultimately, this focus on a frictionless experience elevates a modern vending machine from a simple convenience to a genuine employee perk.

Solving Common Mechanical Problems

Even the most robust, reliable vending machine can experience a glitch. It’s the nature of any complex equipment. The good news for facility managers is that most issues are minor mechanical hiccups that a professional technician can resolve in minutes. Understanding the common causes of downtime helps demystify the process.

The primary goal is uptime. You need your employees and guests to have reliable access to refreshments. When a machine requires service, the issue almost always falls into one of three categories: a payment system error, a product jam, or a communication fault between components. A professional service provider knows exactly where to look.

Payment System Errors

One of the most frequent service requests involves a bill acceptor or coin mechanism that stops working. Often, the culprit is remarkably simple. A crumpled dollar bill, a foreign coin, or even pocket lint can cause an obstruction. These payment validators use sensitive optical scanners and precise guides, so any foreign object can block the sensors, causing them to reject all payments as a security measure.

A technician can typically resolve this quickly by:

Resetting the System: A simple power cycle can often clear minor software glitches that cause payment systems to freeze.

Clearing Obstructions: They can open the payment modules to easily remove any jammed currency or debris.

Recalibrating Sensors: Periodically, sensors require recalibration to ensure they accurately read modern currency and maintain security.

These are standard, routine fixes that keep transactions flowing smoothly and minimize disruption.

Product Dispensing Jams

The classic stuck product is a familiar frustration. This is another common mechanical issue, particularly in older coil-style machines. It usually happens when a product's packaging snags on the spiral or when an item is improperly loaded. Fortunately, most modern vending machine mechanics include guaranteed delivery sensors that have largely solved this, but jams can still occur.

The key to resolving a product jam is identifying the point of failure. A technician can manually turn the coil, reposition the product, or adjust the spiral's spacing to better accommodate certain items, preventing future occurrences.

This hands-on expertise is what ensures a machine operates without a hitch. To learn more about what a professional service call entails, our corporate guide to reliable vending services breaks down the entire process. It’s all about a proactive service approach.

Simple Troubleshooting Tips for Facility Managers

While you should always rely on a trained technician for repairs, there are a couple of things you can check. If a machine is completely unresponsive, confirm it’s plugged in securely and that the circuit breaker hasn’t tripped. It sounds obvious, but it’s a common oversight.

For payment issues, suggesting users try a flat, crisp bill can sometimes resolve acceptance problems. These quick checks can occasionally prevent an unnecessary service call and get the machine operational again immediately.

Why Proactive Maintenance Is So Important for Businesses

A vending machine that functions flawlessly every time is not a matter of luck. It's the direct result of a structured, proactive maintenance program.

Consider it like the HVAC system in your building—you wouldn't wait for it to fail on the hottest day of the year. You perform regular preventative maintenance to keep it running efficiently. The same principle applies to the complex vending machine mechanics that provide refreshments to your team around the clock.

A premier vending operator doesn't wait for service calls. They adhere to a strict schedule of preventative care, addressing minor issues before they escalate into major problems that cause downtime. This is the cornerstone of a truly dependable corporate vending service.

The Anatomy of a Proactive Checkup

A professional maintenance visit goes far beyond simply refilling products. It’s a comprehensive inspection of the machine's critical systems to ensure optimal performance. This detailed attention is what guarantees a smooth, frustration-free experience for your employees and guests.

So, what does a standard checkup include?

Cleaning Internal Parts: Dust, crumbs, and spillage are the enemies of mechanical components. Technicians clean dispensing mechanisms, payment systems, and cooling fans to prevent jams and overheating.

Calibrating Payment Systems: They test and fine-tune bill and coin acceptors to ensure they correctly identify all current currency, minimizing payment rejection errors.

Inspecting Dispensing Motors: Each motor is tested to confirm it is rotating correctly and with sufficient torque. This is critical to preventing product jams and ensuring successful vends.

Verifying Refrigeration Temperatures: For any machine serving cold drinks or fresh food, the technician confirms the cooling unit is maintaining the correct temperature, a crucial step for product safety and quality.

Extending Lifespan and Ensuring Quality

This commitment to preventative care does more than just prevent downtime—it extends the machine's operational lifespan, protecting the investment and ensuring it runs reliably for years. When selecting a vending partner, inquiring about their maintenance schedule is essential. It reveals their commitment to quality and a truly worry-free service. This approach aligns with modern facility management, a topic we cover in our guide on 8 facility management best practices for 2025.

Proactive maintenance is the difference between a vending machine that works most of the time and a vending service you never have to think about. It transforms a piece of equipment into a reliable workplace amenity.

The global vending machine market is currently valued at around USD 23 billion and is poised for significant growth, driven by innovations like cashless payments and smart inventory management. You can find more details in a report on the global vending machine market at Precedence Research. This growth underscores the importance of keeping these sophisticated machines in peak condition. By resolving potential issues before they arise, a vending provider demonstrates a commitment not just to their equipment, but to the satisfaction of your employees and clients.

Your Questions About Vending Machine Mechanics, Answered

When considering a vending solution for your company, it's easy to get lost in the technical details. However, most questions from facility managers and HR leaders boil down to three key areas: reliability, product variety, and operational efficiency.

Getting clear answers ensures you are confident in selecting the right vending partner for your business needs. Let's address the most common questions about how modern vending machines truly work.

How Reliable Are Modern Vending Machines?

Today’s vending machines are engineered for high-demand corporate environments. Their exceptional reliability stems from the smart technology inside. Most new machines feature self-diagnostic systems that continuously monitor their own operational health.

This functions like a check-engine light, flagging potential issues with a motor or payment sensor long before it causes a failure. Paired with remote monitoring, a professional operator can often diagnose and dispatch a technician to fix a problem before your employees are even aware of it. With a robust proactive maintenance schedule, machine uptime is incredibly high, ensuring the service is a dependable amenity for your team.

Can New Vending Machines Sell Fresh or Fragile Items?

Absolutely. The limitations of older spiral coils are a thing of the past. The mechanics inside today's machines are far more advanced, designed to handle a wide range of products.

Conveyor belts are ideal for gently moving delicate items like salads or sandwiches to the retrieval bin without damage.

Elevator-based systems carefully lift and lower fragile products such as glass bottles or yogurt cups, eliminating any risk of dropping them.

This mechanical innovation is what enables a modern vending program to offer a diverse and appealing product selection. To see how this technology supports healthier workplace options, check out [your corporate guide to healthy, fresh vending solutions](https://www.vendmoore.com/post/your-corporate-guide-to-healthy-fresh-vending-solutions).

The ability to safely vend fresh food and fragile items is a game-changer for corporate wellness. It transforms the breakroom from a simple snack stop into a genuine dining amenity, improving employee satisfaction and well-being.

What Stops a Product From Getting Stuck?

This classic vending machine frustration has been virtually eliminated by modern technology. Most current machines feature an infrared sensor system—often called a “guaranteed delivery” system—at the bottom of the cabinet.

This sensor projects an invisible beam of light across the retrieval area. If a user makes a purchase and the sensor does not detect an item breaking that beam, the machine's software knows the vend has failed. It will then automatically attempt to turn the spiral a second time or, more commonly, issue an instant refund. It’s a simple yet crucial feature that ensures no one loses money or walks away frustrated.

Are Modern Vending Machines Energy Efficient?

Yes. Energy efficiency is a core design principle for modern vending machine mechanics. Manufacturers have integrated energy-saving technology to lower operating costs and help companies achieve their sustainability goals.

Key features include low-power LED lighting, high-performance insulation to maintain internal temperatures with less compressor runtime, and highly efficient cooling systems. Many machines also have programmable low-power modes that activate during off-hours, such as nights and weekends. This focus on efficiency makes providing on-site refreshments both cost-effective and environmentally responsible.

Ready to provide your team with a reliable, modern, and hassle-free vending experience? At Vendmoore, we specialize in creating customized vending programs that align with the unique needs of your business. Our commitment to proactive maintenance and the latest technology ensures your machines are always stocked, fully operational, and ready to serve.

_edited.png)

Comments